Services

Our Location

68, 1 Mai Boulevard, Constanța

Email Us

Call Us

+40 (720) 085951

Contact us

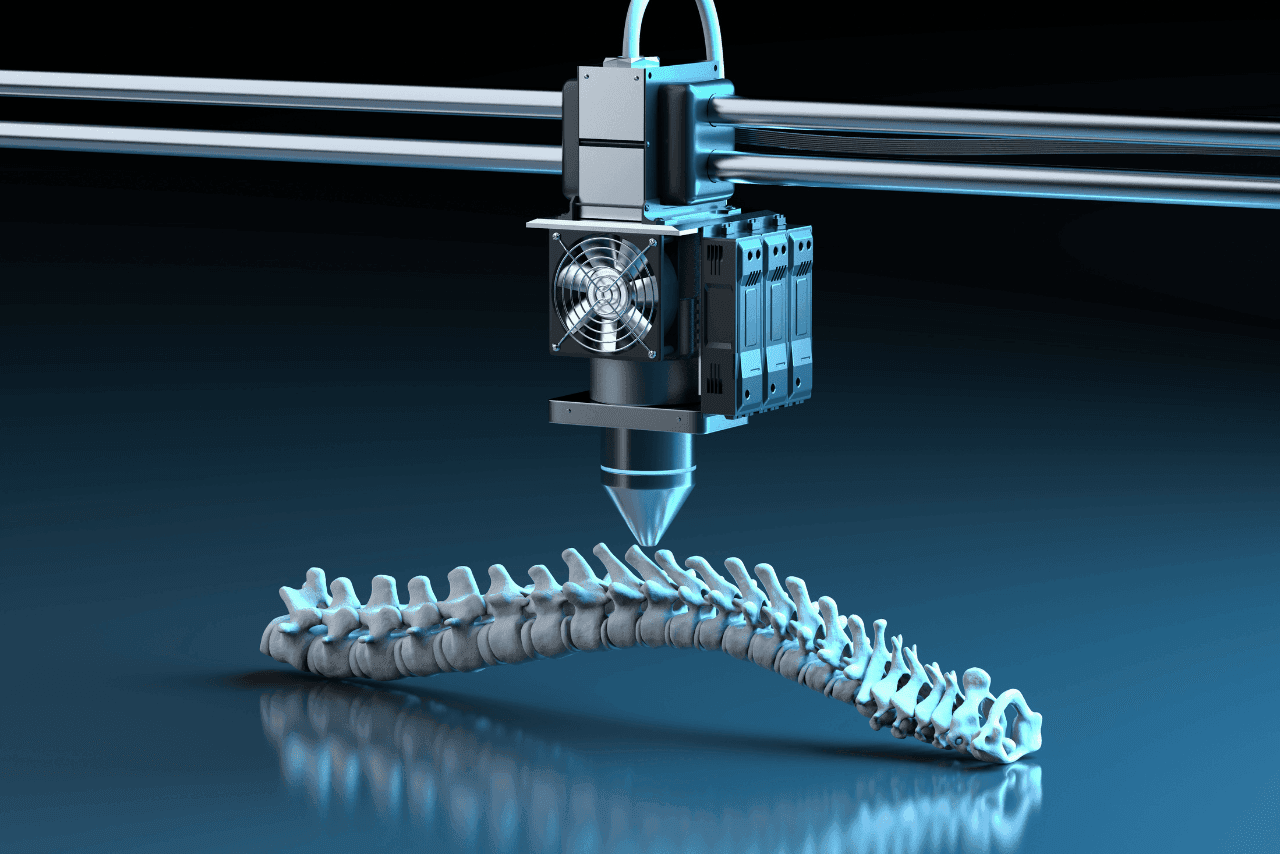

3D Printing (FDM) (Fused Deposition Modeling)

Prices

The price for 3D FDM printing differs depending on the material and complexity. Prices start from 2 euro/hour of printing.

Duration

Estimating time for printing and shipping will be approched after a brief convertation about the project.

Quality

The size of the layers contributes to the quality of the products

Layer sizes:

– Extra Fine: 0.06 mm

– Fine: 0.1 mm

– Normal: 0.15 mm

– Fast: 0.2 mm

– Extra Fast: 0.3 mm

Materials that our printers can work with:

The printers with which our workshop is equipped support a wide variety of materials. The material is chosen depending on the utility of the final product and the conditions it is subject to. Below you will find the list of materials along with their advantages and disadvantages to choose the best option for your project.

1. Polylactic Acid (PLA)

PLA ( Polylactic Acid) filament is a popular material used in 3D Printing, known for its ease of use, affordability, and eco-friendliness. It is a biodegradable thermoplastic derived from renewable resources such as cornstarch or sugarcane.

Advantages:

PLA is favored by beginners and professionals alike due to its low printing temperature, minimal warping, and lack of harmful fumes during printing. It is available in various colors and can produce detailed and smooth prints.

Disadvantages:

PLA is less heat-resistant and durable compared to other filaments like ABS.

Applications:

PLA is more suitable for decorative objects, prototypes, and low-stress applications.

2. Polyethylene terephthalate glycol (PET-G)

Advantages of PET-G:

Mechanical and chemical resistance, at high temperatures, dimensional stability (does not deform over time), compatible with food.

Disadvantages:

The rigidity makes this material not exactly suitable for applications where it requires flexibility or deformability. It is less resistant to impact than ABS.

Applications:

PET-G is a suitable material for prototypes and functionals, packaging and containers, components for the food industry, household items, toys and entertainment items, lighting elements, medical and laboratory components.

3. Carbon Fiber

Disadvantages:

High costs, electrical conductivity (advantageous in certain applications), reduced voltage resistance in certain directions, non-uniformity of mechanical properties.

4. Acrylonitrile Styrene Acrylate (ASA)

ASA (Acrylonitrile Styrene Acrylate) has many similarities with ABS filament, but boasts several distinct properties that set it apart. Known for its excellent UV resistance, it is highly resistant to degradation and fading when exposed to sunlight, making it an ideal choice for outdoor applications. In addition, ASA has superior weather resistance, resisting harsh environmental conditions, such as humidity, heat, without compromising its structural integrity.

Benefits:

Weather resistance, high temperatures, mechanical and chemical resistance, dimensional stability (objects printed with ASA do not deform or lose their shape over time), food compatibility.

Disadvantages: Slightly higher costs compared to other materials, unpleasant smell when printing, contraction (shrinkage) during the cooling process.

Applications: Prototypes and functional parts, outdoor components, automotive and transport components, objects for the marine environment, electrical and electronic components, lighting elements, shields and protections.

5. Polypropylene (PP)

PP (polypropylene) filament is a thermoplastic material that belongs to the class of polymers. This material has a molecular structure composed of repeating units of propylene and is one of the most used thermoplastics in the world.

Benefits:

Corrosion resistance, lightness and durability, resistance to high temperatures, flexibility and elasticity.

Disadvantages:

Poor adhesion between layers, difficulty in obtaining a smooth surface, sensitivity to thermal deformation during printing.

Applications:

Packaging, industrial parts and components, replacement of metal parts, medical products, household components.